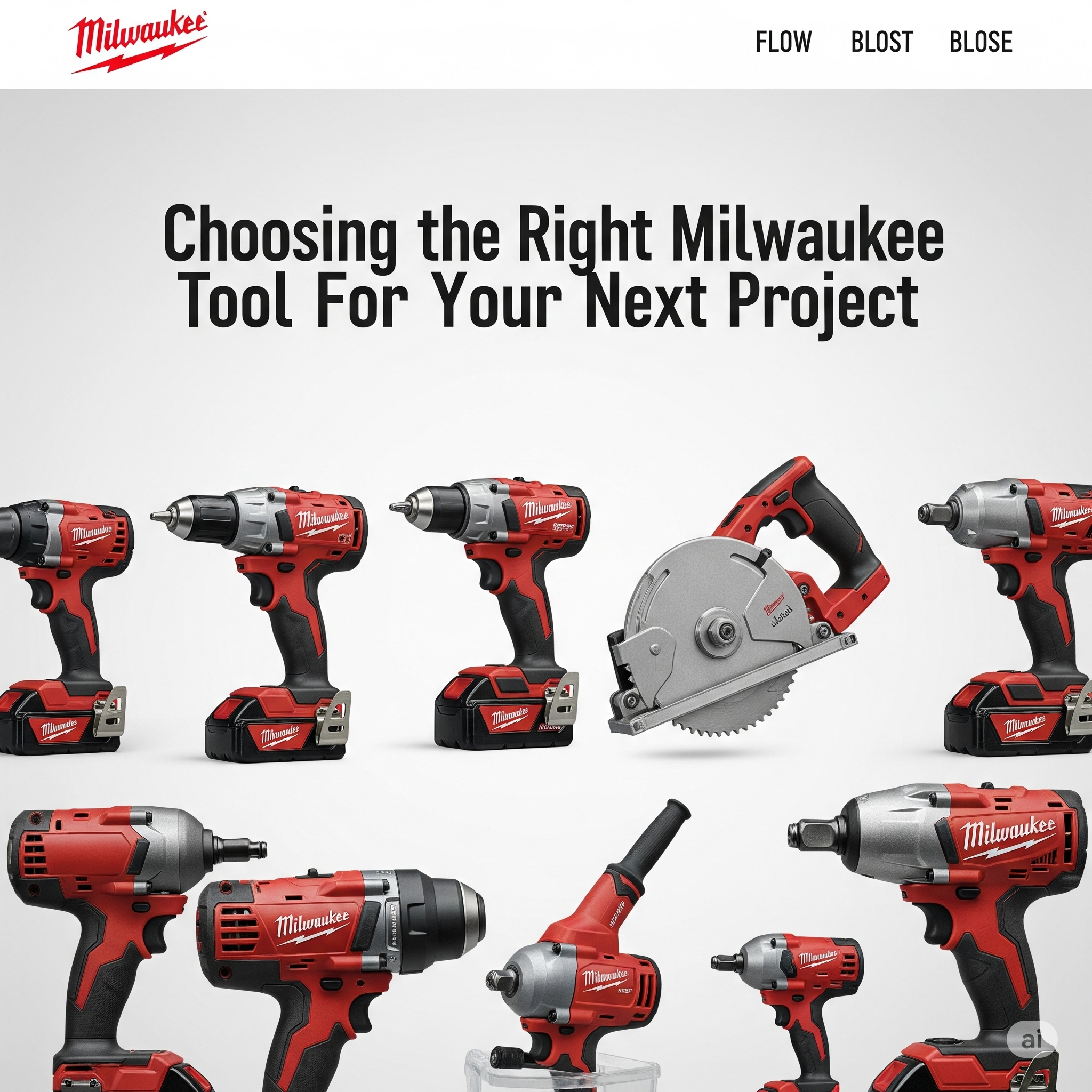

Introduction

Selecting the perfect Milwaukee tool for your upcoming project can significantly impact your efficiency, the quality of your work, and ultimately, your satisfaction with the outcome. With a vast array of powerful and innovative tools available, understanding your project requirements and the specific capabilities of each tool is crucial. This guide will walk you through the key considerations to help you make the right choice.

1. Understand Your Project Requirements:

Before even browsing through Milwaukee’s impressive lineup, take a step back and clearly define the scope and demands of your project. Consider the following:

- Material Type and Thickness: Will you be working with wood, metal, concrete, drywall, or a combination? Different materials require specific cutting, drilling, or fastening mechanisms and power levels.

- Frequency of Use: Is this a one-time DIY task, a recurring hobby, or daily professional use? For frequent or heavy-duty applications, investing in higher-performance and more durable tools like the M18 FUEL™ series is often worthwhile.

- Power Source: Do you need the portability of cordless tools or the consistent power of corded options? Milwaukee’s M12™, M18™, and MX FUEL™ platforms offer a range of cordless solutions with varying power and run-time.

- Specific Tasks: Will you be primarily drilling, driving screws, sawing, grinding, demolition, or a combination of tasks? Identifying the core functions needed will narrow down your options.

- Work Environment: Will you be working in tight spaces, overhead, or in demanding weather conditions? Consider the size, weight, and ergonomic design of the tool.

2. Explore Milwaukee’s Tool Categories and Key Features:

Once you have a clear understanding of your project needs, familiarize yourself with Milwaukee’s main tool categories and their distinguishing features:

- Drills and Drivers:

- Drill Drivers: Versatile for drilling holes and driving screws. Look for features like clutch settings for precise fastening, variable speed for different materials, and brushless motors (FUEL™) for enhanced power and run-time.

- Impact Drivers: Designed for high-speed screw and bolt driving, especially for larger fasteners. They deliver rotational bursts of power (impacts).

- Rotary Hammers: Ideal for drilling into concrete, brick, and masonry. They combine rotation with a hammering action.

- Specialty Drills: Including SDS-Plus and SDS-Max hammers for heavier demolition and concrete work, and right-angle drills for tight spaces.

- Saws:

- Circular Saws: For straight cuts in wood, metal, and other materials. Consider blade size, cutting depth, and cordless vs. corded options. FUEL™ models offer power comparable to corded saws.

- Reciprocating Saws (Sawzalls®): Versatile for demolition, rough cutting, and cutting through various materials. Look for features like orbital action for aggressive cutting and vibration reduction.

- Jigsaws: For making curved and intricate cuts in wood, metal, and plastic. Consider variable speed and blade change mechanisms.

- Miter Saws: For precise angle and crosscuts, primarily in wood. Available in corded and cordless options for jobsite flexibility.

- Grinders and Sanders:

- Angle Grinders: For cutting, grinding, and polishing metal, stone, and other materials. Consider disc size and power requirements. FUEL™ grinders offer corded-like performance.

- Sanders: Including random orbit, belt, and detail sanders for achieving smooth surfaces on wood, metal, and other materials.

- Fastening Tools:

- Impact Wrenches: For tightening and loosening nuts and bolts, essential for automotive and industrial applications. Look for torque ratings.

- Nailers and Staplers: For efficient fastening in construction, carpentry, and upholstery. Available in pneumatic and cordless options.

- Specialty Tools: Milwaukee also offers a wide range of specialty tools like vacuums, lights, inspection cameras, and plumbing and electrical-specific tools.

3. Consider the Milwaukee Ecosystem:

Milwaukee’s commitment to its battery platforms (M12™, M18™, and MX FUEL™) offers significant advantages:

- Interchangeable Batteries: If you already own Milwaukee tools within a specific platform, you can often use the same batteries across different tools, saving you money and reducing clutter.

- System Compatibility: Choosing tools within a single platform ensures seamless integration and consistent performance.

4. Read Reviews and Compare Models:

Before making a final decision, take the time to read online reviews and compare different Milwaukee models within your chosen category. Pay attention to user feedback regarding:

- Performance and Power: Does the tool deliver the expected results for the intended applications?

- Durability and Build Quality: Can the tool withstand the rigors of your work environment?

- Ergonomics and Comfort: Is the tool comfortable to use for extended periods?

- Battery Life (for cordless tools): Does the battery provide sufficient run-time for your needs?

- Features and Functionality: Does the tool offer the specific features you require?

- Value for Money: Does the tool offer a good balance of performance, features, and price?

5. Consider Purchasing Options at G-Ray Tools:

At G-Ray Tools, we offer a wide selection of Milwaukee power tools to meet the needs of professionals and DIY enthusiasts alike. Our knowledgeable team can provide expert advice and help you choose the right tool for your specific project. We also offer:

- Competitive Pricing: Ensuring you get the best value for your investment.

- Fast, Free Shipping: Delivering your chosen tools quickly and conveniently.

- Expert Customer Support: Assisting you with any questions or concerns you may have.

Conclusion:

Choosing the right Milwaukee tool involves a thoughtful assessment of your project requirements, an understanding of the available tool categories and features, consideration of the Milwaukee ecosystem, and research through reviews and comparisons. By following this guide and leveraging the expertise and selection at G-Ray Tools, you can confidently select the perfect Milwaukee tool to tackle your next project with efficiency and precision.

How to Maintain Your Milwaukee Tools for Longevity and Performance

Investing in high-quality Milwaukee tools is a smart decision for any professional or serious DIYer. To ensure these tools continue to deliver peak performance and last for years to come, proper maintenance is essential. This guide outlines key steps you can take to keep your Milwaukee tools in optimal condition.

1. Regular Cleaning:

Dust, debris, and grime buildup can significantly impact the performance and lifespan of your tools. Make it a habit to clean your tools after each use:

- Cordless Tools: Remove the battery before cleaning. Use a soft brush or compressed air to remove dust and debris from vents, housings, and moving parts. Wipe down the exterior with a damp cloth. Avoid using harsh chemicals or solvents that could damage the plastic or rubber components.

- Corded Tools: Ensure the tool is unplugged. Follow the same cleaning procedures as cordless tools, paying attention to the cord and plug for any signs of damage.

- Power Tool Accessories: Clean drill bits, saw blades, grinding discs, and other accessories after each use to remove material buildup. This helps maintain their sharpness and efficiency.

2. Battery Care (for Cordless Tools):

Milwaukee’s REDLITHIUM™ batteries are designed for durability, but proper care will maximize their lifespan and performance:

- Storage: Store batteries in a cool, dry place away from direct sunlight and extreme temperatures. Avoid storing them fully discharged or fully charged for extended periods. Aim for a charge level between 40% and 80% for long-term storage.

- Charging: Use only genuine Milwaukee chargers designed for your specific battery platform (M12™, M18™, or MX FUEL™). Avoid overcharging batteries by removing them from the charger once they are fully charged.

- Usage: Avoid completely depleting batteries during use, if possible. The REDLINK PLUS™ intelligence helps prevent over-discharge, but it’s good practice to recharge them before they are fully drained.

- Cleaning Contacts: Periodically clean the battery terminals and tool contacts with a clean, dry cloth to ensure good conductivity.

3. Lubrication:

Moving parts in your Milwaukee tools require proper lubrication to reduce friction, prevent wear, and ensure smooth operation:

- Follow Manufacturer Recommendations: Consult your tool’s manual for specific lubrication instructions and recommended lubricants.

- Gears and Gearboxes: Some tools have sealed gearboxes that require periodic professional servicing. Others may have grease fittings for manual lubrication. Use the recommended grease type.

- Chucks and Collets: Apply a light lubricant to the jaws of drill chucks and collets to prevent rust and ensure smooth operation.

- Reciprocating Saw Clamps: Lightly lubricate the blade clamp mechanism to ensure easy blade changes.

4. Inspection and Maintenance:

Regularly inspect your Milwaukee tools for any signs of wear, damage, or loose parts:

- Power Cords and Plugs (for corded tools): Check for fraying, cuts, or loose connections. Damaged cords should be replaced immediately by a qualified technician.

- Switches and Controls: Ensure switches operate smoothly and are free from debris.

- Fasteners: Check for loose screws, bolts, and other fasteners and tighten them as needed.

- Guards and Safety Features: Ensure all safety guards and features are in place and functioning correctly. Never operate a tool with missing or damaged safety components.

- Cracks or Damage: Inspect housings and other components for cracks or damage. Damaged tools should be taken out of service and repaired by an authorized service center.

- Worn Parts: Check for signs of wear on components like brushes (for brushed motors), belts, and bearings. Replace worn parts promptly to prevent further damage and maintain performance.

5. Proper Storage:

Storing your Milwaukee tools correctly will protect them from damage and environmental factors:

- Toolboxes and Cases: Use dedicated toolboxes or carrying cases to protect your tools from dust, moisture, and impact during storage and transport.

- Dry Environment: Store tools in a dry environment to prevent rust and corrosion. Avoid damp basements or sheds.

- Temperature Control: Avoid storing tools in extreme temperatures, as this can damage batteries and other components.

- Secure Storage: Store tools in a secure location to prevent theft and unauthorized use.

6. Professional Servicing:

For more complex maintenance or repairs, it’s recommended to take your Milwaukee tools to an authorized service center. Qualified technicians have the expertise and genuine parts to ensure your tools are serviced correctly and safely. Refer to your tool’s manual or the Milwaukee website for authorized service locations.

By following these maintenance tips, you can significantly extend the lifespan and maintain the optimal performance of your Milwaukee tools, ensuring they are always ready to tackle your next project with power and reliability.